A staff of scientists has developed a technique of utilizing organisms known as microalgae, a microscopic phytoplankton usually present in freshwater and marine techniques, to create inks for 3D printing. The platform affords extra environmentally pleasant constructing blocks for the burgeoning 3D printing market.

3D printing is a computer-controlled course of that creates 3D objects by depositing stable supplies additively, typically layer by layer, utilizing mild or laser scanning — the stable materials is derived from liquid inks or resins.

3D printing has develop into more and more essential in industries that use advanced components to finish merchandise. This contains the creation of medical units, the automotive business, aerospace, and even accessibility. Not solely is 3D printing additionally on the rise within the dwelling, however it’s even getting used now to create modular homes.

Many challenges face the 3D printing business as scientists search to spice up the velocity of the method and likewise allow the creation of even finer characteristic sizes, in addition to making 3D laser printers extra compact and cheaper.

One main drawback is at the moment going through this additive manufacturing process is the truth that 3D printing inks typically depend on petroleum-based monomers and different components. Not solely are these not environmentally pleasant, they will even be poisonous.

This has led to the seek for extra environmentally pleasant 3D printing inks and resins with a wealth of various supplies at the moment being investigated. This analysis means that the answer to this problem already exists in nature within the type of microalgae that would function a renewable biomass supply as a substitute of fossil fuel-derived supplies.

Inexperienced 3D printing with microalgae

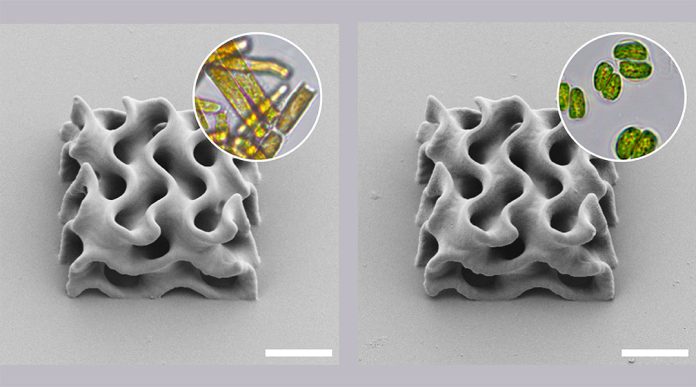

The staff’s analysis printed within the journal Superior Supplies means that two strains of microalgae, Odontella aurita (O. aurita) and Tetraselmis striata (T. striata), might be used as “biofactories” that may generate supplies that may be 3D printed in excessive decision.

“Extracts from microalgae can be utilized as printable supplies (inks) for 3D printing with excessive decision utilizing a laser-based know-how known as two-photon 3D laser printing,” defined Eva Blasco of Heidelberg College, Germany, and PI on the Excellence Cluster 3D Matter Made to Order (3DMM2O). “Microalgae may be seen as microscopic biofactories for the following technology of sustainable, biobased, and biocompatible supplies which have the potential to revolutionize supplies science.”

Blasco continued by explaining that microalgae-based inks may overcome the environmental drawbacks of present merchandise by offering a extra sustainable and eco-friendly various to petroleum-based 3D printing supplies.

The brand new method is environmentally pleasant as a result of throughout their cultivation, microalgae can carry out “carbon fixation” changing atmospheric carbon dioxide into natural molecules. Moreover, microalgae don’t compete with meals crops for arable land, not like some plant-based bioplastics.

Blasco stated this makes them a extra viable possibility for large-scale manufacturing with out impacting meals provides. Moreover, the cultivation of microalgae doesn’t require recent water, that means wastewater may even be used, thus providing fascinating alternate options to wastewater therapy routes. She added that printed supplies derived from microalgae are biocompatible, opening new potentialities in bioengineering functions.

The staff was notably excited about fatty and hydrophobic natural compounds within the microalgae known as lipids, particularly these primarily composed of triglycerides, the principle constituents of physique fats in people and different animals, in addition to composing vegetable fats. Not solely does microalgae develop sooner than different vegetable oil crops, however the lipid yield of those organisms is larger, too.

Blasco added that within the case of microalgae, these fatty acids are extremely unsaturated, that means they’ve two or extra carbon atoms which might be joined by a double or triple bond, which implies that they are often mixed with extra atoms or radicals. The double bonds of those unsaturated fatty acids can thus be used for functionalization with printable teams.

“The thought of utilizing microorganisms as biofactories for the technology of purposeful supplies, particularly within the subject of 3D printing, is unexplored,” Blasco stated. “Moreover, microalgae are a novel feedstock since they comprise fascinating metabolites for each monomers and photoinitiators that may straight yield inks for 3D printing with out counting on exterior and infrequently non-biobased components.”

The fabric devised by the staff confirmed glorious biocompatibility, permitting 3D printing with out the addition of photoinitiators, molecules that soak up photons when mild is shone on them and type reactive species out of the resultant excited state, which might then provoke additional reactions.

“The truth that the microalgae inherently contained inexperienced pigments, reminiscent of chlorophyll derivatives, which may efficiently exchange standard photoinitiators, was fairly stunning,” Blasco stated. “This opens new alternatives in functions in life sciences since ‘commonplace’ photoinitiators are normally poisonous.”

Scaling up the ink

The staff’s microalgae various carried out very properly throughout testing, efficiently creating 3D microstructures with sub-micron decision. Its efficiency was corresponding to present 3D printing inks and resins for two-photon 3D laser printing.

“The offered method labored for 2 microalgae from totally different households, particularly O. aurita and T. striata, demonstrating its versatility, broad applicability, and thus its affect,” stated Clara Vazquez-Martel, first creator of the publication and a Ph.D. candidate in Blasco’s group. “Different microalgae strains would in all probability be appropriate as properly and needs to be explored sooner or later.”

She continued by explaining that the developed technique is sort of straightforward and easy, that means that it may simply be scaled up to be used outdoors of the lab.

“Our companions on the Spanish Financial institution of Algae are already working with photobioreactors of various volumes in addition to raceways-type tradition tanks for even bigger-scale cultivation,” Vazquez-Martel stated. “We’re additionally contemplating exploring different strategies that may speed up the entire course of. To maneuver in direction of an ideal round supplies economic system, we need to examine the biodegradability in addition to end-of-life functions of 3D printed constructions.

“If we handle to shut the loop, microalgae-based supplies can be used, and, after their purposeful lifetime, these supplies can degrade on-demand, for instance, producing vitamins for the following cycle of microalgae cultivation.”

Reference: E. Blasco, et al., Printing Inexperienced: Microalgae-Based mostly Supplies for 3D Printing with Gentle, Superior Supplies, (2024). DOI: 10.1002/adma.202402786